FITGO Custom Fast Lacing System Quality Assurance

If you have any consulting services, please contact us

ABNORMAL PROBLEM

EXCEPTION DESCRIPTION: THE ROPE IS BROKEN (1)---THE ROPE CANNOT BE FASTENED

Causes:

Worrying the rope is not strong enough, and cut it to test with a sharp tool.

The correct way:

There is no need to use any sharp tools to cut the test. Fitgo has tested the tensile strength of 35-90kgf or more to meet various application scenarios under normal wear.

ABNORMAL DESCRIPTION: LOOSE ROPE (2) --- UNABLE TO FASTEN THE ROPE

Causes:

If the rope is knotted, the end of the rope is not tightened or the length of the end of the rope is shorter than 2 to 3 mm, which leads to the loosening of the rope and the looseness of the rope, thought the rope is broken.

The correct way:

Strictly follow the SOP "Installation Guidelines", tie the nylon rope with a double figure-eight knot and tighten the knot, leaving the length of the tail at 2 to 3 mm.

ABNORMAL DESCRIPTION: 2 ERRS OF THE KNOB ARE BROKEN

Causes:

The disassembly/assembly method is incorrect. Forcibly break the two ears of the knob.

The correct way:

Strictly follow the Fitgo operation guide to implement the "Webpage --- Technical Support --- Operation Guide (2) the corresponding product model to do the correct disassembly/assembly"

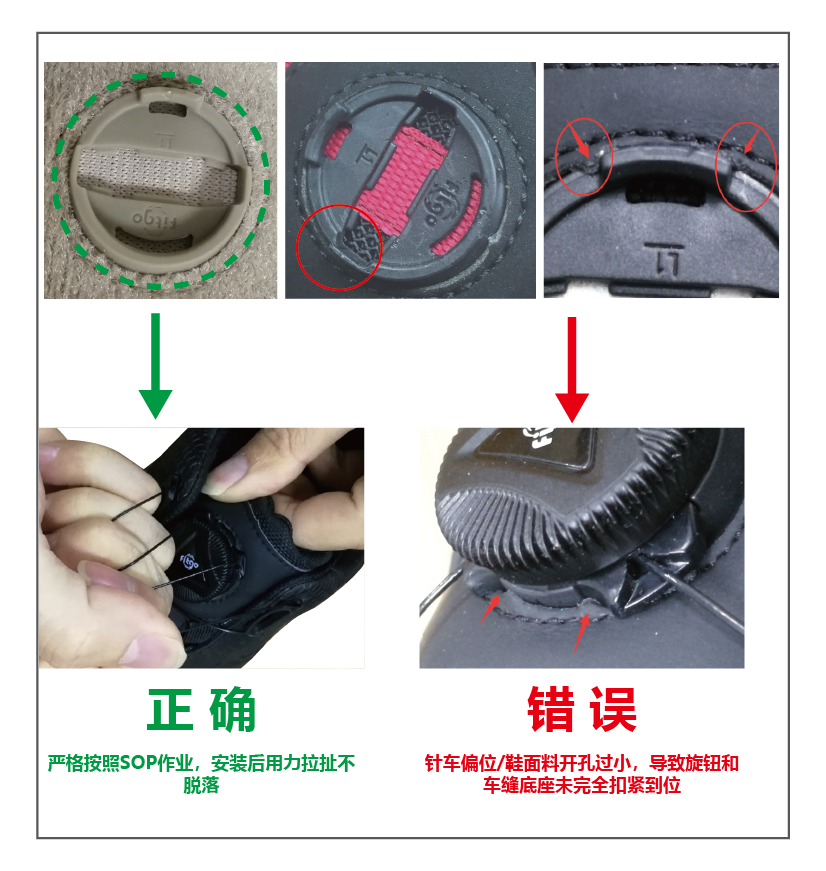

ABNORMAL DESCRIPTION: THE KNOB FALLS OFF

Causes:

1. The knob is not completely inserted into the buckle groove of the sewing base;

2. The sewing base did not sew or drill as required.

The correct way:

1. Checking the knob completely clamped to the sewing base before delivery, and Pull it up by hand;

2. Training operators to strictly follow the SOP "Knob Installation Inspection and Sewing Base Sewing Regulations".

EXCEPTION DESCRIPYION: ROTATION IS SLIGHTLY STUCK

Causes:

The knot at the end of the rope is not tightened as required, the tail is too long, it’s not pulled into the reel wheel, and interferes with the sewing base when rotating.

The correct way:

Strictly follow the SOP "Installation Guidelines", tie the nylon rope with a double figure eight knot and tighten the knot, leaving the length of the rope tail at 2 to 3 mm, and pull it into the reel wheel.

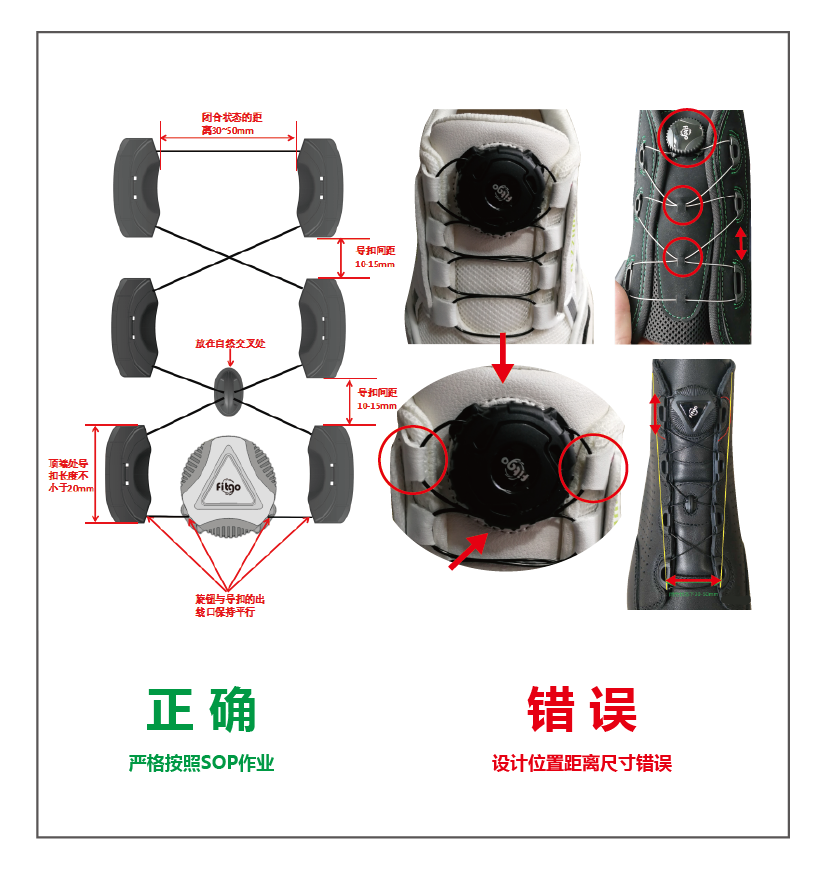

ABNORMAL DESCRIPTION: THE KNOB INTERFERES WITH THE ROPE---THE RESISTANCE OF ROTATING AND TIGHTENING THE ROPE IS TOO LARGE

Causes:

1. The top lace guide is too short, and the closing distance of the upper is too small;

2. The direction of the knob is wrong, the distance between the lace guide is long, and the cross position of the rope is install incorrectly;

3. The top lace guide is too short, which causes interference with the knob at the intersection of the ropes.

The correct way:

1. The top lace guide model should be at least 20MM, and the closing distance of the upper should be 25-50MM;

2. The outlet of knob 2 ears on the shoe tongue should be installed upward, and the outlet of knob 2 ears on the side should be facing inward. The distance between lace guide is less than 15MM.

3.The top lace guide should be at least 20mm or more, and the design of the outlet of the knob 2 ear should be flush with the lace guide.